About us

From Seed to Solution

The seed for Cable Ways was planted in 1984 when there was repeated demand for unavailable “data networking distribution hardware.” Research revealed a clear product gap in both local and international markets.

With an engineering mindset, solutions were designed and manufacturing began, using Connector Systems - a local distributor - to supply the New Zealand market

What started as a small domestic operation quickly expanded through demand and in 1987, Cable Ways Ltd was formally established. Its success grew as the company expanded into Australia, Asia, Europe, and the Pacific Islands.

The early range of data distribution rack mounting hardware quickly expanded into enclosures to mount the associated active equipment. The family of “Wall Frame” cabinets was followed by a range of configurable free standing 19” cabinets. This range of “Panel Support Cabinets,” became the core of production, meeting installer needs for individual cabinets and corporate server farm applications.

As exchange technology changed, the need to move active distribution equipment into urban and rural environments opened a new cabinet opportunity. Cable Ways followed the demand, creating a family of “Outside Plant Cabinets,” which were the forerunners in NZ Telecom’s active equipment dispersion.

Leading the Way

Cable Ways is a recognised name in New Zealand’s telecommunications, transport, water, and utility sectors, offering integrated solutions that meet network requirements and infrastructure demands. Our experience covers both indoor and outdoor cabinets, which are engineered to withstand New Zealand's extreme environmental conditions.

Our solutions are particularly valued for their seismic resilience, ensuring reliable operation in earthquake-prone regions. Whether it is protecting critical telecommunication networks or vital infrastructure in challenging conditions, Cable Ways’ cabinets offer the durability and performance needed for long-term, uninterrupted service and peace of mind.

Beyond their physical toughness, our outdoor cabinets feature specialised coatings that can withstand the wear and tear of graffiti, preserving the aesthetics and functionality of the installation site over time.

With over 37 years in this industry, we continue to deliver innovative solutions that are contractor-friendly, using smart, cost-effective in-house manufacturing. We take pride in our unwavering commitment to deliver custom enclosures of the highest quality designed for the unique environments in which they operate.

Our Core

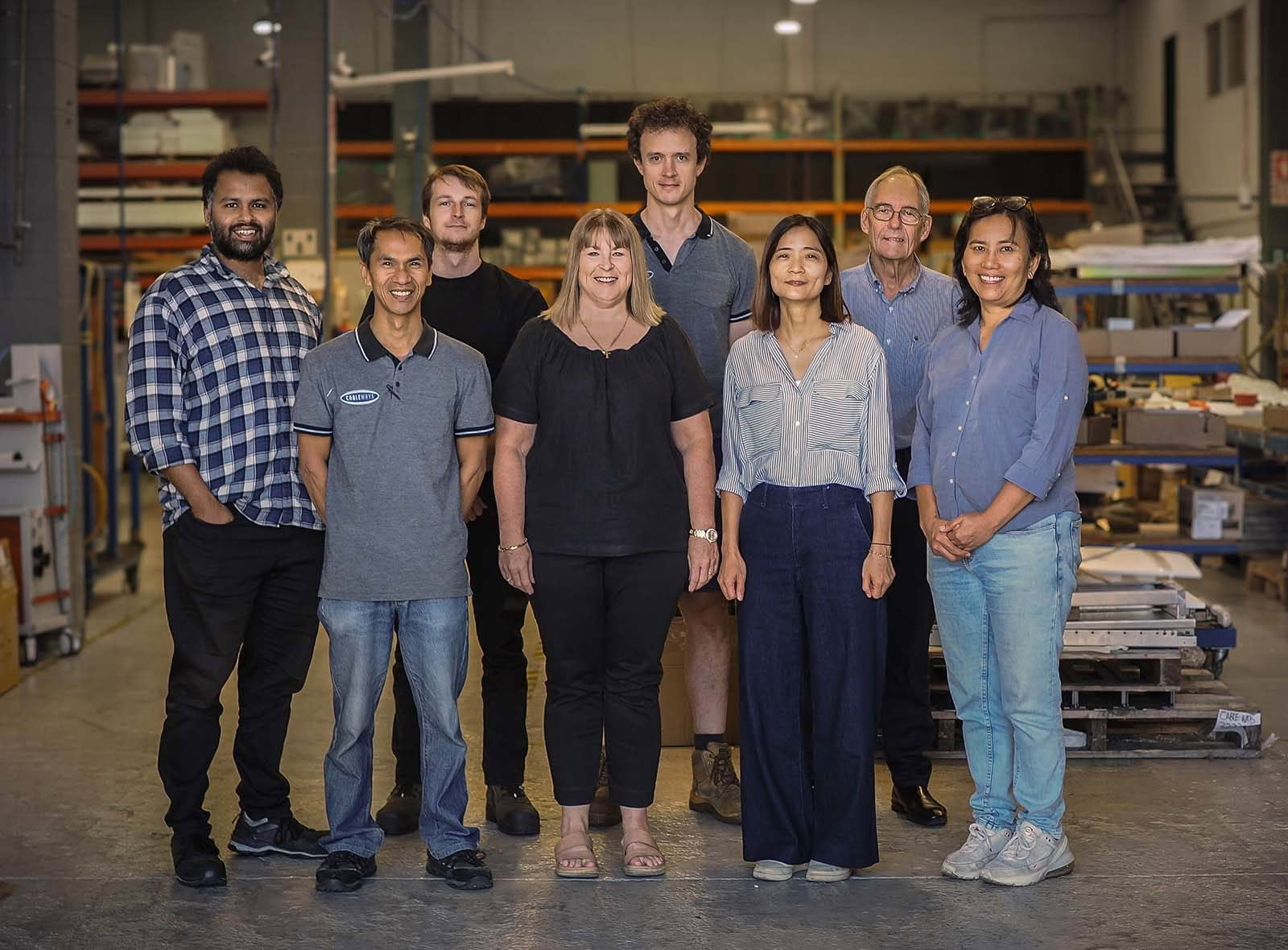

We are a tightly integrated company with our success attributed to our skilled and experienced team of committed staff.

As a people-first company, our team is at the core of our operations. We value our employees, whose average service period exceeds 13 years, and endeavor to create a workplace that encourages and supports personal growth and development.

All relationships matter to us, and we enjoy long-term associations with many customers.

By way of an example, from an initial, unique cabinet solution and project rollout for 230 sites, we continue to manufacture similar and other cabinets for the same corporation 25 years later.

Our passion is to continue and build yet stronger relationships with our clients, by delivering progressive, dependable, cost-effective enclosure solutions.

Our Capabilities

We operate a vertically integrated manufacturing plant developed over many years to accommodate 95% of all fabrication and assembly requirements.

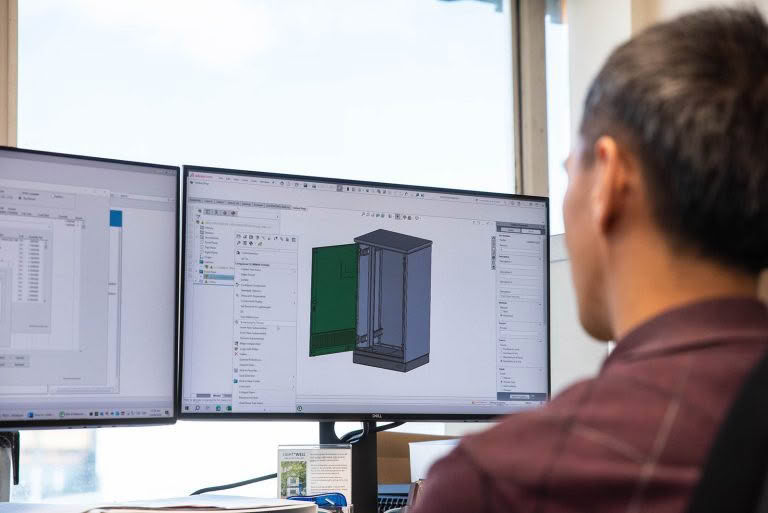

Our engineering office uses Solidworks models to directly integrate their designs into the production management software, saving time, whilst eliminating error and waste.

The fully equipped aluminum and steel fabrication plant features programmable machinery for punching, folding, and extrusion cutting. The in-house plastics division allows flexibility for our design engineers to prototype novel solutions and integrate them into production without delay. The electrical division delivers cabinet solutions focused on reducing customer installation costs, often supplied ready for direct equipment integration, complete with main switchboard, service wiring, DC power and VRLA or LFP batteries.

In essence, we have adopted a flexible manufacturing approach, allowing simple, fast and effective product customisation, without unnecessary or wasted effort. This flexibility allows us to offer optimized bespoke solutions, without the more common set of development overheads.

Our Mission

To provide quality, cost-effective solutions that meet the highest standards.

We take pride in delivering products on time, to specification, and within budget. Our team is dedicated to working closely with clients, understanding their unique needs and delivering innovative solutions that exceed expectations.

David Hobday founded Cable Ways with a clear vision to provide the New Zealand market with durable, high-quality products, designed for cost-effective local production. With a background in mechanical and electronic engineering, David’s leadership and innovative approach has shaped Cable Ways into a trusted name in the industry. His commitment to excellence ensures that Cable Ways products continue to set the standard for performance and reliability.

Our team

Kayla Chuang, originally from Taiwan, is known for her precision in sourcing and quality control. Her role as Purchasing Manager ensures that all materials meet the highest standards for durability and functionality, particularly in relation to New Zealand's demanding environmental conditions. Kayla’s production expertise and attention to detail, play a key role in ensuring timely deliveries and the high quality of Cable Ways products.

Our team is made up of multi-skilled, individuals who work across various disciplines and collaborate closely, to deliver integrated solutions to our clients. With strong backgrounds in electrical, mechanical, and mechatronic engineering, they handle both manufacturing and assembly with flexibility and expertise. From advanced machinery to precise cable management, every component is built with care, accuracy, and attention to detail.

Our team brings together sales, administration, and engineering people with different backgrounds, all working together to ensure solutions are tailored to meet your needs. With a collaborative spirit, we combine technical expertise and customer experience to deliver cabinet solutions on time and within specification. From concept to delivery, we’re here to provide innovative, reliable solutions to simplify your application.